Solutions for Corrosion, Abrasion, Clogging, Contamination, and Gas Handling

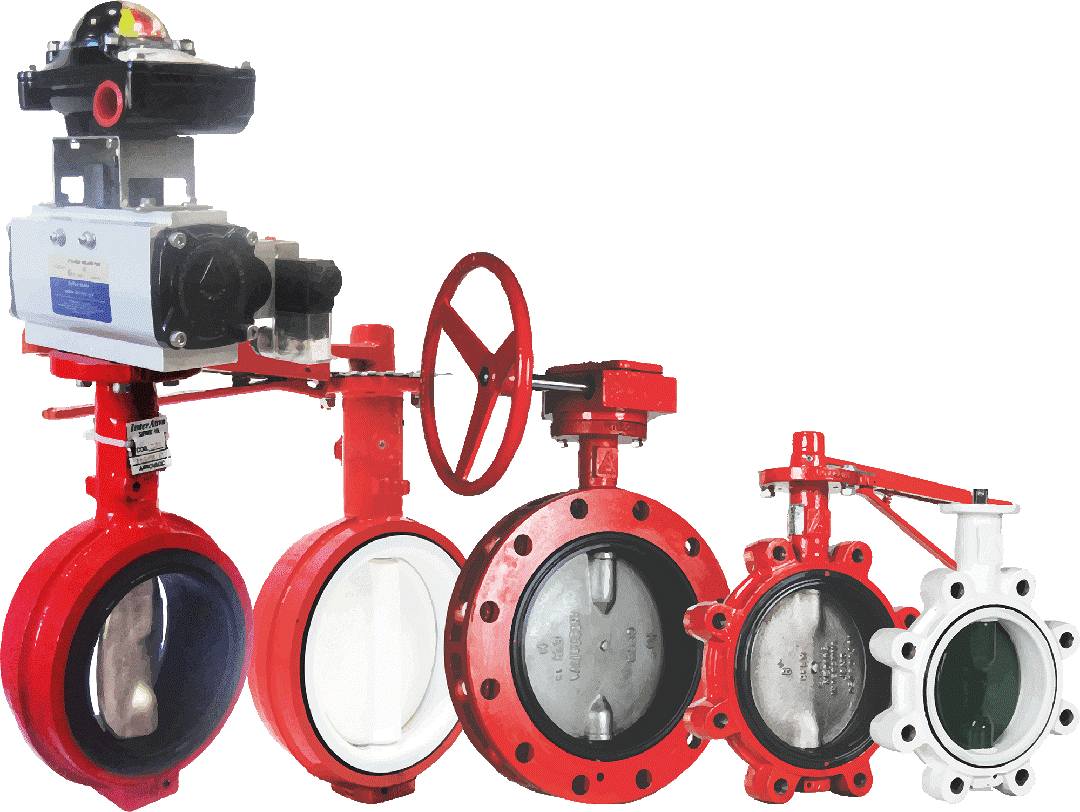

Hand and pneumatic-operated butterfly valves are efficient, quick-opening valves featuring a metal disc (lined if needed) with pivot axes perpendicular to the flow direction in the pipe. These valves are leak-proof across various substances including liquids, slurries, granular materials, powders, pastes, gases, and acids.

Resilient Seated Concept :

Metal-on-Metal Concept :

Disc Materials :

Design/Dimensions :

Disc Materials :

Inspection Tests :

Options :